Table of Contents

The idle air control valve, also known as the idle control valve, is found in the majority of road going vehicles as a management component.

Its purpose is to regulate and control the speed of the idle engine, decreasing and increasing it as necessary to keep up with operating conditions.

What About Driving With A Bad Idle Air Control Valve?

The idle control valve is vital to any vehicle. It may appear a tiny component, but when it fails to function correctly, it can cause all sorts of issues with your car.

Sometimes it may render the vehicle un-drivable.

Bad Air Control Valve

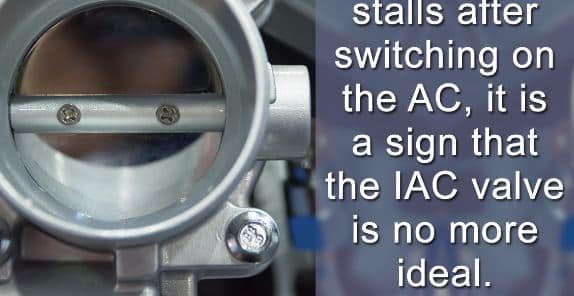

So, driving with a bad idle air control valve is sometimes impossible. In some cases, a bad idle air control valve may cause hard starting.

But before the IAC fails, you can learn from the symptoms and take the necessary step to deal with the issue.

How an Idle Air Control Valve Works

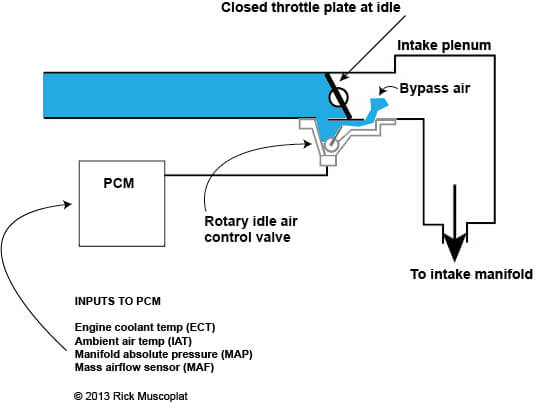

Depending on the condition of your vehicle, IAC determines the decrease or increase of the RPM in your engine.

The engine speed of a vehicle refers to the number of revolutions it makes per minute.

How an Idle Air Control Valve Works

For instance, if your vehicle is heating too quickly or has a heavy load, then the IAC valve will adjust the RPM by decreasing or increasing it, respectively.

This allows the engine to cool down or handle the heavier load.

The engine control unit is designed to manage the IAC valve. And then, the central computer receives information about the level of the temperature and load of the engine; the IAC uses this information to help make proper adjustments.

Based on the information collected from the computer, the valve will be able to respond and regulate the engine RPM better.

Identifying Idle Speed Problems

Before you conclude the valve has a problem, first exhaust all other areas that may mimic the IAC issue.

For instance, if the speed of the engine is stalling, too high, or too low, that automatically rules out the issue of idle speed control system, but the problem is an engine vacuum leak. When checking the health of your valve, first check any possibility of vacuum leaks.

What Happens When the Idle Air Control Valve Goes Bad

When checking the vacuum leak, the most common condition is to find the IAC valve extension out.

That normally means the engine has an air leak, and the computer engine is trying to bring the idle speed back down by closing the idle air bypass circuit.

In case, there is a shorted or open circuit in the IAC solenoid, the idle speed or driver circuit is out of range, it will habitually set one or more fault-codes and turn on the check engine light.

If the light is turned on, you have to plug a scan tool into the diagnostic connector and read out the codes that set the light.

The majority of modern cars are designed with a “Drive-by-Wire” induction system. These cars use an angle sensor on the throttle pedal to calculate throttle input.

After that, the computer engine will activate a small motor on the throttle body, which, too, has a position sensor so the computer can match the throttle pedal angle to the throttle plate angle.

Normally, the “Drive-by-Wire” vehicles typically do not have an IAC valve because the computer will take the information from all sensors and adjust the throttle plate angle automatically as necessary.

An idle malfunction may require cleaning or the replacement of the throttle body. As well as the use of a professional scanner to have the system reset.

The materials you need to do that are as shown below:

- Vehicles service manual

- Pipe cleaners or Q-Tips

- Digital Multimeter

- Professional vehicle scanner

- Intake Cleaner / Throttle Body

- Checking the IAC function by disabling it

Here are steps you need to follow to disable IAC

- Step 1: For you to check the IAC valve, you have to consult the vehicle service manual to access the location of the IAC valve on your car.

- Step 2: Make sure you disconnect the IAC valve. When you do that, locate the IAC valve electrical connector and unplug the idle control valve.

- Step 3: Start the engine. After starting the engine, observe how the car reacts. Where the car may have previously been experiencing a stall after every start-up, disabling the idle control valve may open the bypass circuit and cause the car to idle to rise when the valve is disabled.

Disable iac in car

-

Step 4: Reconnect the IAC valve. When doing that, ensure you turn off the ignition and reconnect the IAC valve electrical connector.

-

Step 5: Start the engine. The engine is idle at this point and should function to normal. In case it fails, the idle control valve may be working correctly.

If not, try another method to check and see if it requires to be cleaned.

Inspect the Valve Visually

- Step 1: When you gain access to the IAC valve, consult the car manual for the IAC location on your vehicle

- Step 2: Find the IAC valve electrical connector and disconnect the idle control valve

- Step 3: Follow the car service manual to remove the IAC valve

- Step 4: Take time to inspect the IAC valve and the mounting location for dirt, rust or carbon build-up. Inspect the IAC valve mounting location and pintle for damage.

- Step 5: Use intake cleaner solvent or carbon cleaner to remove dirt and build-up from the IAC valve. Utilize the straw that comes with the spray can to clean the IAC valve mounting location and bypass the passage as well.

- Step 6: You have to install the idle control valve with a new seal because using the old type may cause a vacuum leak or a coolant leak on vehicles where coolant runs through the IAC valve.

- Step 7: In case you used a lot of solvents, that may cause the engine to run rough momentarily when taking in and burns off the entire solvent. After some time of running rough, the idle should return to normal.

Using A Multimeter To Check IAC Valve Resistance Specification

-

Step 1: Locate the IAC valve following vehicle service manual

-

Step 2: Disconnect the IAC valve electrical connector once you locate it

-

Step 3: According to the procedure details in the vehicle service manual, remove the idle control valve.

Using A Multimeter To Check IAC Valve Resistance

-

Step 4: Inspect the valve and the mounting location for rust, carbon build-up, or dirt. Take time to inspect the IAC valve mounting location and Pintle for damage. Before you condemn the IAC valve, ensure you rule these items first.

-

Step 5: Utilize the specification listed in the manual service of your car for the IAC valve and follow the guideline on how to test the valve using a digital multi-meter against the electrical terminal pins on the idle control valve electrical connector.

If you see the reading fall within the specification, know that the valve should be electronically sound; the problem lies somewhere else.

You have to replace the unit with a new one if the reading is within the specification.

Conclusion

We hope you read this entire article if you are driving with a bad idle air control valve. If the voltmeter shows a reading outside the normal range, make sure you buy a new idle air control valve.

Unless you understand the ins and outs of auto repair, you’ll need to search for an expert to perform the replacement job. Having a replacement of a new IAC may restore things to normal if you are certain about the condition of the previous one.

After you master the symptom of an IAC with an issue, you can prevent the need to purchase a new idle control valve. Also, you can hire a professional technician to help you determine if the IAC valve requires a replacement.

by

by